Action | Cut arrow shaft shorter |

|---|---|

Impact | Arrow acts stiffer |

Action | Increase length of arrow shaft |

Impact | Arrow acts weaker |

Action | Add point weight |

Impact | Arrow acts weaker |

Action | Decrease point weight |

Impact | Arrow acts stiffer |

Action | Add weight to back of arrow |

Impact | Arrow acts stiffer |

Action | Reduce weight to back of arrow |

Impact | Arrow acts weaker |

Action | Increase draw weight |

Impact | Arrow acts weaker |

Action | Decrease draw weight |

Impact | Arrow acts stiffer |

Action | Impact |

|---|---|

Cut arrow shaft shorter | Arrow acts stiffer |

Increase length of arrow shaft | Arrow acts weaker |

Add point weight | Arrow acts weaker |

Decrease point weight | Arrow acts stiffer |

Add weight to back of arrow | Arrow acts stiffer |

Reduce weight to back of arrow | Arrow acts weaker |

Increase draw weight | Arrow acts weaker |

Decrease draw weight | Arrow acts stiffer |

Every level of bowhunter would benefit from building their own arrows. An initial investment of only a couple of hundred dollars can get you all the tools you’ll need to build your own arrows forever. Building your own arrows is not all that complicated and will allow you to build a superior product to what you get from a box store. Plus, by building your own, you will get straighter, more accurate and consistent arrows. So, what are you waiting for? It’s time to get the gear and this article will give you everything you need to know to build your own arrows! The best part, everything you need to build your own arrows can be found in the GOHUNT Gear Shop!

There are so many options for arrows on the market. They vary in straightness, weight tolerance, stiffness, diameter, materials and price. There are seemingly endless combinations beyond that for point weight, vanes, nocks and arrow length. If you are just getting started I’m sure it can seem overwhelming, but it’s actually pretty simple and there are some very good resources to help. When it comes to arrow "straightness" you can check out an article I wrote comparing .0025" vs .006" arrows.

Before I get too much farther, I should note that you need an arrow that has just the right amount of stiffness or spine for your setup. If it’s too weak or too stiff it will not fly accurately. Arrows come in common static spine categories: 200, 250, 300, 340, 400 and 500. Perhaps a bit backwards from what you might think, but the smaller that number, the STIFFER the spine.

The length of your arrow, the point weight, vanes, draw weight and draw length will impact how stiff or flexible your arrow will react when shot. Once you have an arrow set up with a broadhead and vanes and are shooting it from your bow, it will react dynamically.

This means that the dynamic spine is a critical component of picking an accurate hunting arrow and understanding how to manipulate the spine of an arrow to get the best flight for you is even more so. The following table will indicate the actions you can take to impact the spine to work for you.

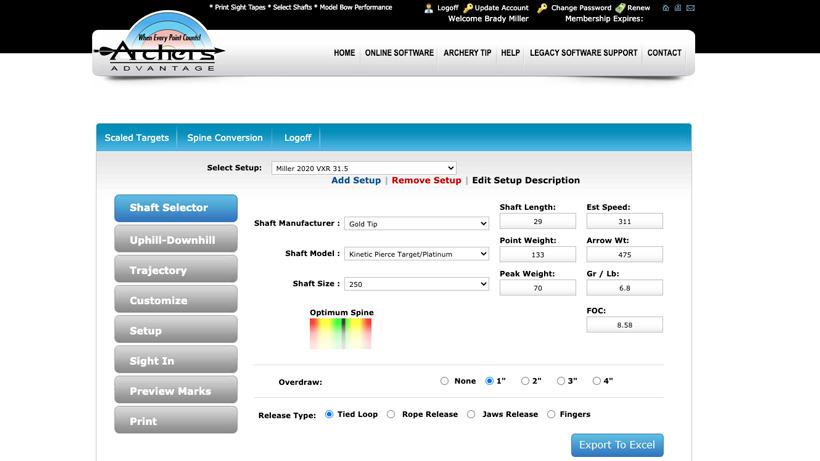

For $12 anyone can sign up for an online account at Archers Advantage Online. Their “shaft selector” program is easy to use and allows you to input your exact setup and then play with different options of arrows and components to give you a really solid idea on what arrow you should shoot.

For example, I can create a profile for my 2022 hunting bow, which is a Mathews V3X 33, at 30” DL and 68# DW. Afterward, I can go to the arrow configuration section and input the arrow I would like to research as well as the components: insert weight, outsert weight (if you use one), point weight, vanes weight, nock, collar and wrap. I can also input the length of the arrow I am thinking about shooting. For starters, I often begin with an arrow 1” shorter (carbon to carbon) than my draw length.

After I have input all of the aspects of the arrow I am interested in, I can click on the “shaft selector” link and I will see a bunch of information that will help me make my choice. One of the first things I check is the visual representation of how well the spine I selected fits my setup. The green portion of the graph would indicate that the spine is perfect. To the left the green into the yellow and red portion of the graph would indicate your spine or stiffness is too weak. To the right of the green would indicate it’s too stiff. Ideally, you would like your arrow to be right in the middle to even a little stiff for a fixed blade broadhead.

If your arrow of choice is too stiff or too weak, you can use the table above to manipulate the spine to work for you. If you cannot, you can also consider using a stiffer or weaker spined arrow. Overall, the Archers Advantage program can help you immensely. Along with selecting the arrow, you can see things like estimated front-of-center, finished arrow weight and speed.

A couple more thoughts on selecting arrow shafts: Arrow companies offer different options in terms of straightness and weight tolerance per dozen. For example, the Gold Tip Pro Hunter Arrows have a straightness tolerance of +/- .001” and weight tolerance of +/- .5 grains. The Hunter XT version of the same arrow has straightness tolerances of +/- .003” and weight tolerance of +/- 2 grains. They are also about $30 more a dozen.

I once heard someone say, “Well, it’s archery, so absolutely everyone has an opinion,” especially when it comes to vane selection. What’s best? Three vane, four vane, high profile or low profile shield cut, left helical or right helical? There are so many options, but here are a few principles you should keep in mind:

My personal preference is three vanes like the AAE Max Stealth Vanes or the TAC Summit Vanes, fletched with helical Bitzenburger clamp and about a 2 to 3 degree offset. For reference, I shoot Slick Trick 100 grain Standard Broadheads, QAD Exodus heads and Tooth of the Arrow broadheads all with good results.

Once you have the shafts and vanes you need, it’s time to start building arrows. The first step I take is to quickly square the end of the arrow I am going to use as the guide end to make my first cut. I do that with a G5 arrow squaring device.

First cut? Yes. Typically, the straightest part of the arrow shaft is the center portion of the arrow so I like to cut from both ends to get the straightest part of the arrow. It would seem to reason that the shorter the arrow, the better your chances of getting a really straight arrow. If you have a long draw length, buying straighter arrows is probably worth it. If you shoot shorter arrows, you can probably buy cheaper arrows and cut them from both ends to get a dozen arrows that are still really straight.

After I have made my first cut, I then square the ends that were cut with my G5 arrow squaring device and then I cut each arrow from the other end. After that cut, I square that end and I now have a dozen shafts that are cut from both ends and squared.

Before I begin to assemble arrows, I prefer to spin each arrow shaft on a Pine Ridge arrow spinner and check for straightness. Within a few seconds of spinning each arrow I can get a relatively good idea of which shafts are the straightest. Then, I place them in groups, straightest (A), medium (B) and the wobblers (C). Then I will go through and mark each arrow with a silver pen accordingly: A1, A2, B1, B2, C1, C2...etc. Next, I go through and weigh each arrow shaft on a Last Chance Archery grain scale and I either write the weight down or record it in a spreadsheet.

Once that’s completed, I open up my packs of arrow components — vanes, inserts, nocks — and I weigh those for consistency. I have never had real inconsistencies in inserts or nocks, but, occasionally, you may see some variance in vane weights. It might take you sorting through a pack or two of vanes to get them all to weigh the same. The reality is that the benefits of weighing and categorizing arrows and components are mostly in your head, but I’ll take any advantage I can get.

What I am looking for is at least six arrows from a dozen that are straight and weigh within a grain or two of each other. Those will be my hunting arrows and I feel like I owe the animal my best effort.

The next step is to clean the interior portion of the insert end of the shaft and glue the inserts in. To clean the inside of the arrow shaft, I use a cotton Q-tip dipped in 100% acetone and I swab the inside of the arrow until there is no carbon residue on the Q-tip. After I have cleaned each one, I will let them sit for fifteen minutes to dry completely. In the meantime, I will quickly soak the aluminum inserts in acetone and allow them to dry.

Using acetone is somewhat contentious. I guarantee someone will read this and tell me that Easton tells you to use isopropyl alcohol to clean carbon arrows and that acetone will damage the carbon bonding. Perhaps it will, but I have personally tried both on Gold Tip and Easton arrows and I get better results from acetone and have had no issues with using it. Use either to your own discretion. I am using acetone, but isopropyl alcohol should work well enough, too. Personally, I use the same glue I use to fletch my vanes to also glue in my inserts. I know there is insert specific glue and epoxy, but to keep it simple, I use the same glue, which is AAE Max Bond. It's tremendously effective in keeping inserts glued in. If you want to be able to get an insert out and replace it, a two part epoxy can be used. To glue them in, simply lay three lines of glue down the length of the insert and turn them in as you push. Spin them a few times to even out any glue inside and then wipe away any excess near the top that’s popped out.

After I have the inserts installed, my next step is to clean the ends of the arrow where I will be installing the vanes. Once again, I use acetone on a rag and I wipe the end of the arrow off until there is no carbon residue left on the rag. I then let the arrows sit for 15 to 20 minutes to dry completely. I would never suggest soaking the arrow in acetone.

To fletch your own arrows, you’ll need a fletching jig. The best on the market is the Last Chance Archery Vane Master Pro. It’s also the most expensive by quite a bit. I have been using a Bitzenburger Dial-O-Fletch right helical jig and clamp for 20 years and it is also a great option. Please read the directions on setting up your jig before you get started. I would also suggest the Zenith Bitzenburger upgrade kit as a worthwhile addition. The upgrade kit replaces your standard nock receiver and provides tighter tolerances by keeping your arrow from moving during the process.

You may also be interested in adding an arrow wrap. An arrow wrap is just a sticker/wrap that you can use to either increase visibility of the arrow or add some personality to it. Applying a wrap is simple. Lay the wrap on a computer mouse pad, line the arrow up and roll it on.

Fletching is relatively easy. First, determine where you want the vane(s) to sit. The closer the vanes are to the back of the arrow, the better they will steer it. Conversely, vanes too far back may contact your face and affect flight. Pick a location that is as far back as you can get it, but is not contacting your face at full draw. I typically mark that spot on my clamp so I can line up each vane as I fletch them.

Prior to fletching each vane, I will, once again, use some acetone on a rag to wipe the base of each vane or you can use an AAE Max Weld Primer Pen. This will eliminate any oils or residue on the vane and help it to adhere better.

Hot tip: When you are selecting each vane for your arrow, hold the vane up and look down the back of it. Many vanes from Bohning and others will have a left or right lean to them, depending on how they were molded or stamped. Match the vanes for each arrow so they all lean the same direction. If you do not, you will get a configuration when you look down the arrow from behind where the vanes appear ever so slightly unevenly spaced.

The next step is to put the vane in the clamp, put a bead of glue down the center of the vane and then apply the clamp in a rolling fashion from the back toward the front. I let it sit for ten seconds or so after doing that. While I wait, I will use a Q-tip and run it along the edge of the vane to remove any excess glue. Then, I pinch the clamp and lift it straight up. Next, I rotate the jig counter-clockwise and repeat the process.

After I have all the vanes glued on, I typically pull the arrow out of the jig and apply a very small bead of glue behind and in front of each vane. This gives each one an added bond to the shaft.

The final step for me is to put the nocks back in and install field tips or broadheads and spin them again on my arrow spinner. I will also weigh each one and, once again, make a note of that in my spreadsheet.

There is a lot of personal satisfaction in building your own arrows. You get a good product and you will never have to wait for someone else to refletch an arrow or build them again. For as little as a few hundred bucks, you can ensure that you will go into the field each fall for the rest of your life with the straightest, most consistent arrows.

Note: this article was originally published in 2020 and has been updated to reflect my new 2022 setup.

Fletch your arrows with some offset or helical. A straight fletch makes for a speedy arrow, but will probably not guide your broadheads well enough.

Shoot just enough vane (either number of vanes or surface area) to adequately guide your broadhead. Any more surface area or helical will slow your arrow down unneededly.

The benefit to a low profile vane is that it gives you slightly more clearances from cables, rest and vegetation during flight. The negative is that you will most likely have to use four vanes or longer vanes to have enough surface area to guide the broadhead. This will increase the weight of your arrow at the fletching end.

The benefit to a high profile vane is that you can most likely shoot a three vane configuration, which reduces weight at the end of your arrow and will still guide your broadhead. The negatives are that they have slightly less clearance and they may produce more sound in flight.

Fletch with vanes of all the same color. This will come in handy later when you may have to nock tune arrows.

Easton 4mm Axis Long Range Match Grade 300 spine cut 29” carbon to carbon

Easton 4mm Half Out 8-32 Aluminum Insert (50 grain)

3 AAE Max Stealth Vanes w/ right helical

Total arrow weight: 465 grains

FOC: 12.7%

Estimated FPS: 294

30” Draw Length

68# Draw Weight w/ 80% Left-off mods

Item | Shaft selector |

|---|---|

Use | Online program to select the right spine, length and components |

Item | |

Use | Used to cut arrows to length |

Item | |

Use | Squares arrow shaft ends to get the best insert, nock and broadhead alignment |

Item | |

Use | Attach vanes and fletchings to arrows |

Item | 100% pure acetone |

Use | Clean arrow shafts and vanes before gluing |

Item | |

Use | Insert and/or vane glue |

Item | Q-tips |

Use | Cleaning inside of shafts and wiping excess glue |

Item | Silver marker |

Use | Used to mark the stiff spine of the arrow shaft |

Item | |

Use | Test and group arrows for straightness |

Item | |

Use | Weigh each component, final arrow weight and categorize arrows |

Item | Use |

|---|---|

Shaft selector | Online program to select the right spine, length and components |

Used to cut arrows to length | |

Squares arrow shaft ends to get the best insert, nock and broadhead alignment | |

Attach vanes and fletchings to arrows | |

100% pure acetone | Clean arrow shafts and vanes before gluing |

Insert and/or vane glue | |

Q-tips | Cleaning inside of shafts and wiping excess glue |

Silver marker | Used to mark the stiff spine of the arrow shaft |

Test and group arrows for straightness | |

Weigh each component, final arrow weight and categorize arrows |